Here you’ll find answers to all your questions about deliveries or placements, assembly, specification texts, standards, qualities and certificates. If you have any further questions, please do not hesitate to contact us.

Frequently asked questions

General information on cooperation with cbs beton

Can I return or exchange goods at CBS Beton?

If you wish to return or exchange goods, we kindly ask you to first contact our sales department.

Goods returned without prior notification will be refused upon receipt and, consequently, will not be processed!

Returns:

Goods in good condition: In all cases, you will be charged an administration and negotiation fee of 10% of the sale value of the items, with a minimum of 125 EUR.

Damaged goods :

agreement with the sales department, a physical inspection of the returned goods will be carried out at the CBS Beton sales site before a decision is made. In the case of slight damage, a loss will be charged according to the condition of the returned goods. If the merchandise is too damaged, a return can always be refused. Any associated costs can never be recovered from CBS Beton and are always at your expense.

Can i buy concrete elements as a private customer?

CBS Beton does not work directly with private customers. You can buy retaining walls through your specialist contractor, gardener or materials store.

Je ne sais pas combien de mètres courants et de quelle hauteur de murs de soutènement j’ai besoin. CBS Beton mesurera-t-elle mon terrain?

We provide price quotations based on customer requests; we do not measure on site. Individuals can call on their groundworker for this.

Does cbs beton also carry out groundworks? Does CBS Beton advise on foundations?

We don’t do groundworks. We give general advice, but the foundation is the responsibility of the contractor.

Can I bring back some panels?

Standard retaining walls can be returned if they have not yet been installed and are in good condition.

When can I pick up an order?

This is possible between 8am and 4.30pm. Pick-up is possible between 6 a.m. and 8 a.m. if the order is placed in advance and CBS Beton is informed. Always state the VO number (order number). Pick-up is not possible on Saturdays.

What service does CBS Beton provide for loading and delivery?

We can load your truck if it is suitable for loading and transporting retaining walls. If the vehicle is not suitable, loading is carried out under the customer’s responsibility. CBS Beton can deliver to your site and also unload. The truck can be placed from the truck as far as the weight of the elements allows, and the crane can travel to the desired location.

Can i buy concrete from CBS Beton?

No, we only manufacture precast concrete in our plant.

Montage

INSTALLATION INSTRUCTIONS FOR CBS BETON, AGRI WALLS

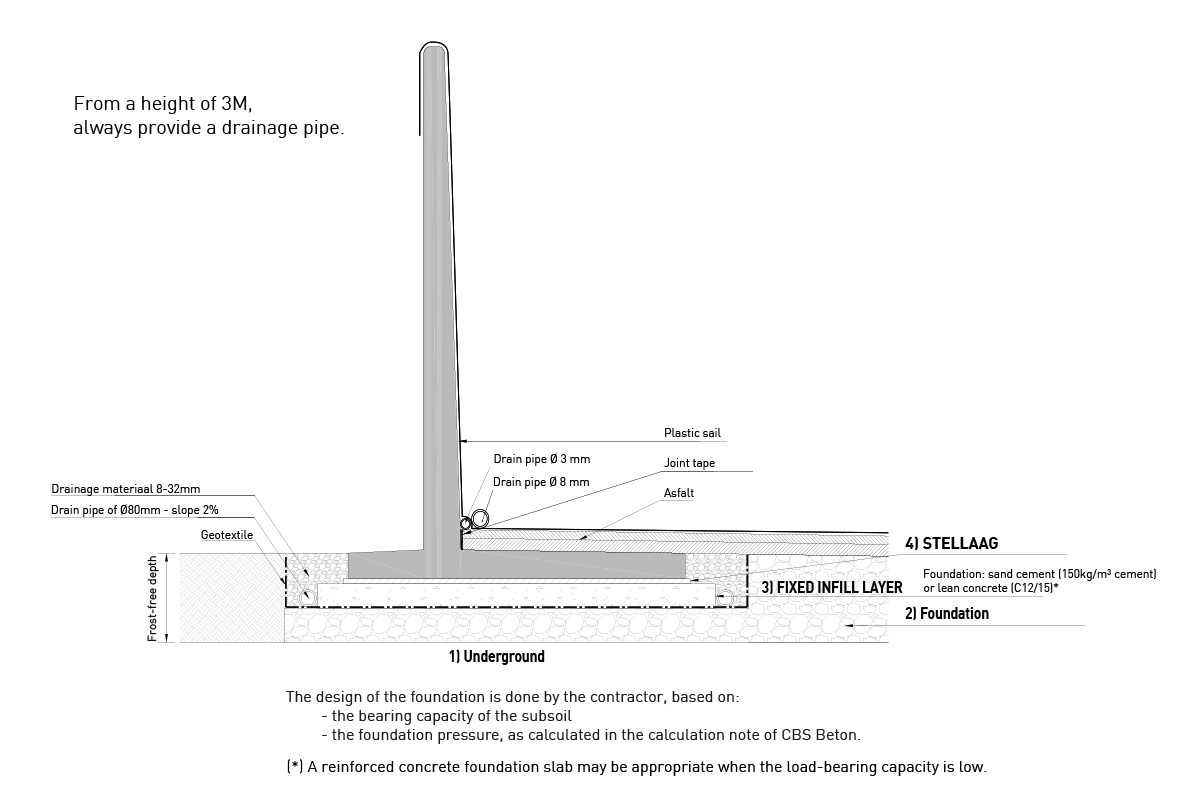

Upon arrival at the site, the site must be fully accessible to all truck and crane traffic. This must be done on a foundation with sufficient bearing capacity for heavy traffic. During installation, the yard must be fully available and no other construction work must take place nearby so that we can ensure optimum safety conditions. Our retaining walls must be placed on a load-bearing foundation that meets the following requirements ;

- Construction of the whole on a raised foundation relative to the sub-foundation.

- The foundation will be less sensitive to possible flooding.

- In the event of flooding, the customer will provide adequate drainage so that the foundation is dry upon placement.

1) HOW TO PREPARE THE FOUNDATION?

- 1.1 SUBSTRATE

The substrate shall be compacted and sufficiently load-bearing, with a compressibility modulus M1 of at least 40 MPa. Possibly improved by adding lime or cement or, if necessary, a build-up with replacement foundation material. This is entirely dependent on the existing situation.

- 1.2 FOUNDATION

The foundation should be constructed with compacted crusher run, possibly with the addition of lime, cement or a bitumen binder. This foundation layer should show a compressibility modulus M1 of at least 100 MPa. The layer thickness depends on the situation on site.

- 1.3 THE SOLID FILLING LAYER

If the foundation in sections 1.1 and 1.2 should not reach the prescribed compressive strength, an intermediate foundation of 10 cm of lean concrete with 150 kg of cement should be applied. This foundation should be mechanically compacted and levelled so that a levelling top layer can be applied.

- 1.4 THE BASE LAYER

The base layer, or foundation layer, should be composed of an unbound crushed stone or sand mixture with a crushed grain structure of no more than 10 mm. The layer thickness depends on aggregate and grain size.

A sand mixture of 0 - 5 mm determines a layer thickness of up to 3 cm. A sand mixture of 0 - 8 mm determines a layer thickness of up to 5 cm. A sand mixture of 0 - 10 mm determines a layer thickness of up to 8 cm.

- 1.5 WIDTH OF FOUNDATION.

The total foundation’s width should exceed the width of the panel by at least 20 cms on each side. This additional width is to be determined by the type of panel that is to be installed. After installation, backfill the sections on both sides to at least the top of the foot to prevent shifting/displacement. Our guarantee applies only if this foundation construction is adhered to. Ropes and attachment points ought to be provided and attached, so installation can start immediately. We are not responsible for dimensions, levels and bearing capacity of the foundation.

Prior to installation, the preparation shall be coordinated and discussed with our person in charge on site. The aim is to achieve a pleasant and effective collaboration.

If above provisions are not met, all resulting costs will have to be charged. Failure to comply with the above provi- sions will result in charges of all consequential costs.

2) CALCULATION REPORT

There is a calculation report for every standard segment. It is available on request. In case of AGRI walls, the base should be filled with a material with a maximum specific gravity of 1000 kg/m3. The maximum silage angle is 30°. The maximum axial load above the bunker silo is between 7 and 20 tonnes (depending on the type of wall - see technical sheet for axial strength) for a vehicle with one-metre-wide wheels, taking into account our specifications. For corn storage, our walls can withstand a storage height of 6-8 m for crushed corn with a dry matter content of at least 33%. For beet pulp silage or other products, a calculation note must always be requested from our design department.

3) LIABILITY

The calculation reports are drawn up according to the Eurocode, including the national annexes. The buyer declares to be sufficiently informed about the properties and application possibilities of the sold goods. The buyer undertakes to use these goods solely for the purpose for which they are intended. He bears sole responsibility for exceeding the recommended stack height and recommended overload. The Agri U-walls should always be backfilled with soil before driving towards the next, adjacent silo.

Our concrete meets the strictest requirements of the European concrete standard NBN EN 206 as to resistance to aggres- sive chemical attack. However, in such specific environments, deterioration of concrete elements cannot be completely ruled out. To maximize durability of the concrete elements and reduce risk of deterioration to an absolute minimum, we recommend combining our concrete elements with silo varnishes, coatings, epoxy or silo foil. This preventive measure applies especially to biogas plants. CBS Beton can under no circumstance be held liable for damages resulting from non-compliance with the instructions for use. Furthermore, any warranty claims are excluded if these instructions are not followed.

4) LIFTING OPERATIONS

If CBS Beton lifts the wall sections to install them in their final position at your construction site, the foundation for the walls must be completed in its entirety. All loads are delivered on large trucks (44 T - 18.5 m long). The customer must ensure access for CBS Concrete’s deliveries.

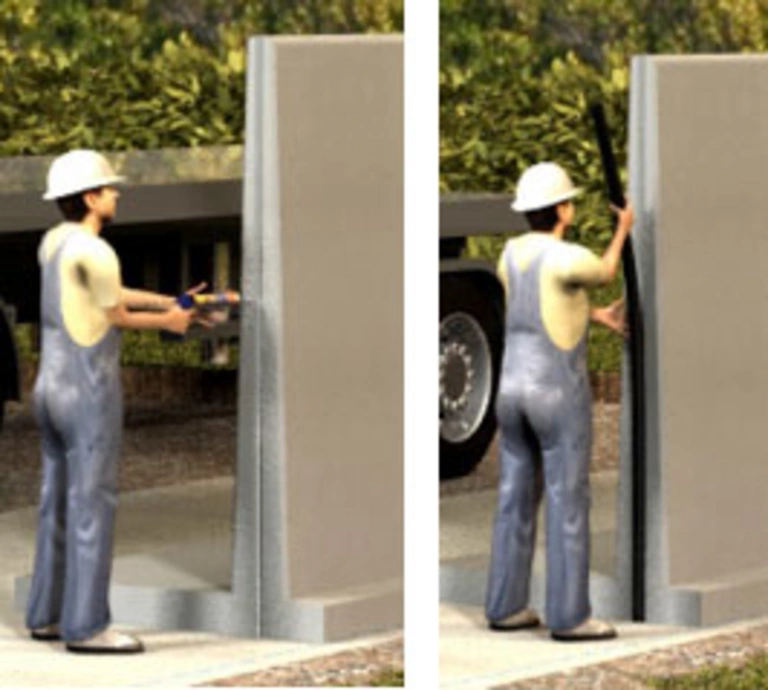

CBS Beton will provide you with a lifting plan/instructions and a risk assessment for the delivery and installation of your walls. Our experienced installation team can install up to 200 m of wall per day. Usually, we lift the sections using a hydraulic manipula-

tor from the back of the truck itself. L and T walls are generally not equipped with lifting anchors. If lifting anchors are required, please state this clearly when ordering.

5) THE JOINTING SYSTEM

When installing the Agri walls, consider the following steps:

- Above and below the groove, apply a dot of Sikaflex.

- Place the slat in the groove.

- Apply duct tape along 1 side to fix the slat in place.

- Install the 2 concrete sections against each other.

- Remove the excess duct tape.

- Apply sealant to the joint.

6) PROTECTION OF YOUR NEW SILO

Even though CBS Concrete’s concrete meets the highest requirements with regard to aggressive chemical environments, CBS Concrete cannot guarantee that the concrete sections can withstand all chemical attacks. Even exposure class XA3 has its limits.

In conditions where the concrete walls are exposed to chemical attack (anaerobic fermentation bunker, storage of corn, grass, sugar beet, etc.), additional protective measures should be ta- ken. One of the most effective measures is protective plastic covering the entire vertical wall.

A minimum dry matter content of 33% is required for corn due to the aggressive behaviour of leachate. The minimum dimensions of your chopped silage should be between 6 and 8 mm. The permitted values of the angle of ensilage, density and angle of internal friction of the stored material as well as the permitted axle load can be found in the calculation reports prepared by our engineering service. Please contact our technical department for other applications. CBS Concrete provides a 10-year warranty if the above conditions are met.

7) THE SILO COVERAGE SYSTEM

We offer 2 systems for covering your roughage in your trench silo.

1) SILAGE SAFE

To optimally protect roughage, Silage Safe offers an innovative roughage cover system. It allows you to ensilage properly airtight in a fast and efficient way.

Covering roughage is often hard and labour-intensive work. Silage Safe coverage system relieves you of this strenuous activity. With Silage Save coverage system you can cover your roughage hermetically after ensilage within half an hour. Thereby optimally preserving the quality of your roughage.

2) EASY SILAGE

With the Easy Silage Portal coverage system, dairy farmers keep their roughage in optimal condition by means of a covering tarp and water system for perfect storage of the roughage. Covering the roughage airtight, quickly and well, ensures perfect conversion into a high-quality product.

Our intelligent coverage system has a fully automatic, self-correcting control system with a remote control powered by a battery and solar panels.

The Easy Silage Portal systems are suitable for stand-alone trench silos up to 100 metres long and 25 metres wide and are easy to operate with a remote control. The portal system itself goes up to 26 m wide. Because every farm is unique, the coverage system is custom assembled.

Delivery & placement

How can CBS Beton help you?

Delivery - placement

Pick-up by you, using a suitable vehicle Delivery to site, unloading by customer Delivery and unloading, with the possibility of depositing the materials at the desired location, with the customer’s help.

No ground work

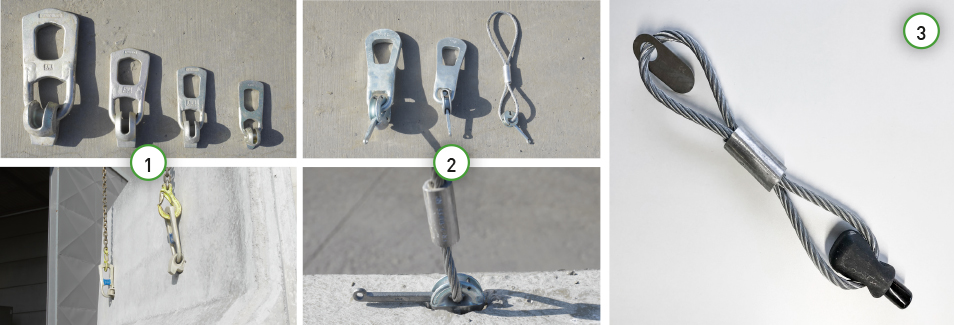

Types of lifting

• Ball head anchors (1) = KKA

• Ring transport anchors (2) = RTA

• Screw anchors = MRD24 - MRD42 (3)

Know-how

Concrete composition according to

NBN EN 206-1: 2000 and NEN EN 206-1: 2001 - self-compacting Strength class: C60/75

Belgian environmental classes and Dutch exposure classes

- Carbonation-induced corrosion: XC4

- Chloride-induced corrosion: XS3 and XD3

- High water saturation with de-icing: XF4

- Highly aggressive chemical environments: XA3

Environment classes

- EE4: Frost and de-icing (presence of water containing de-icing from in-situ melting, splashing or run-off)

- ES4: Submerged elements

- EA3: Environment with high chemical aggressiveness as per table 2 of NBN EN 206-1:2001

Requirement: W/C: 0.45

380 kg cement/m³ minimum

Aggregate complying with EN 12620 with sufficient resistance to freezing and defrosting.

- Sulfate-resistant blast furnace cement

- Concrete facing: maximum 30 mm

- Steel quality: FEB 500

- Fire resistance: 60 minutes

Reinforced concrete elements

For all walls, there is a tolerance of +/- 5 mm on length, width and height measurements.

Tenders

Consult the specification tender for our precast concrete products:

- Specification text CLF10GS models for the Belgian market.

- Specification text DLF10GS models for the Belgian market

- Specification text STANDARD BUILDING models for the Belgian market

Tender specifications clf10gs models for the belgian market

Reference model: CBS BETON model CLF10GS

The retaining elements consist of self-compacting reinforced concrete and are finished smooth on all visible sides. All elements comply with NBN EN 206-1 and with NBN 15-001 within construction class S1. The elements have strength class C60/75 in environmental class EE3 and environmental classes XC4 and XC1.

The retaining elements have a minimum concrete cover of 30 mm and are finished at the top with a set frame and laterally with 10 mm edge strips. The retaining elements are BENOR approved in accordance with NBN B 21-132 and NBN EN 15258. The reinforcement is of type B500A. The retaining elements are CE marked and equipped with ball head anchors so that they can be placed with a chain set. The connection between the retaining walls is via a tongue and groove system. Between the horizontal anchors is a sand gap that allows for perfect alignment of the walls during installation.

In normal use, the retaining walls have an overload of 10 kN/m² for both flat backfilling and slope backfilling of 12 over 4. The retaining walls up to a maximum height of 100cm can also be used inverted as standard under the condition of a foot replenishment of at least 30 percent of the height and a horizontal overload of no more than 5 kN/m². For reversed use with higher walls, appropriate reinforcement is additionally provided.

Tender specification text dlf10gs models for the Belgian market

Reference model: CBS BETON model DLF10GS

The retaining elements consist of self-compacting reinforced concrete and are finished smooth on all visible sides. All elements comply with NBN EN 206-1 and with NBN 15-001 within construction class S1. The elements have strength class C60/75 in environmental class EE3 and environmental classes XC4 and XC1. The retaining elements have a minimum concrete cover of 30 mm and are finished at the top with a set round moulding and laterally with 10 mm edge mouldings.

The retaining elements are BENOR approved in accordance with NBN B 21-132 and NBN EN 15258. The reinforcement is of type B500A. The retaining elements are CE marked and equipped with ball head anchors so that they can be placed with a chain set. The connection between the retaining walls is via a tongue and groove system. Between the horizontal anchors is a sand gap that allows for perfect alignment of the walls during installation. In normal use, the retaining walls have an overburden of 25 kN/m² with a flat backfill. Under a slope backfill of 8 over 4, an additional load of 10 kN/m² is met. The retaining walls also meet the requirements of load model 1 (LM 1) of Eurocode 1 (EN 1991-2) at a distance of 1 meter from the wall.

Tender specification text standard end wall models for the Belgian market market

Reference model: CBS BETON model HEAD WALL

The retaining elements consist of self-compacting reinforced concrete and are finished smooth on all visible sides. All elements comply with NBN EN 206-1 and with NBN 15-001 within construction class S1. The elements have strength class C60/75 in environmental class EE3 and environmental classes XC4 and XC1. The retaining elements have a minimum concrete cover of 30 mm and are finished at the top with a set round moulding and laterally with 10 mm edge mouldings.

The retaining elements are BENOR approved in accordance with NBN B 21-132 and NBN EN 15258. The reinforcement is of type B500A. The retaining elements are CE marked and equipped with ball head anchors so that they can be placed with a chain set. The connection between the retaining walls is via a tongue and groove system. Between the horizontal anchors is a sand gap that allows for perfect alignment of the walls during installation. In normal use, the retaining walls have an overburden of 25 kN/m² with a flat backfill. Under a slope backfill of 8 over 4, an additional load of 10 kN/m² is met. The retaining walls also meet the requirements of load model 1 (LM 1) of Eurocode 1 (EN 1991-2) at a distance of 1 meter from the wall.

Quality, Standards and certificates

For the agriculture and infrastructure market

Did you know ...

CBS Beton is the only manufacturer to hold a BENOR certificate obtained for prefabricated agricultural concrete products in the wall and/or retaining wall elements category for silo and cellar walls. This certificate guarantees that all concrete elements are designed and produced to maximise their lifespan. Our walls also comply with all Belgian and European standards. CBS Beton has an in-house design and engineering office which allows us to develop an appropriate proposal to avoid surprises during the implementation of your project.

CBS Beton’s concrete products are manufactured in accordance with European concrete standard

NBN EN 206: 2013 + A2: 2021 and Belgian national supplement NBN B 15-001: 2018.

Our retaining walls are designed in accordance with the applicable standards.

• NBN EN 1990: Eurocode 0 - Basis for structural design + national annex

• NBN EN 1991: Eurocode 1 - Loads on structures + national annexes

• NBN EN 1992: Eurocode 2 - Design and calculation of concrete structures + national annexes

• NBN EN 1997: Eurocode 7 - Geotechnical design + national annexes

Design principles agriculture:

Concrete strength class: high-strength concrete C60/75

Environmental classes (NBN EN 206: 2013 + A2: 2021)

• XC4: corrosion by carbonation, concrete with reinforcement exposed to air and moisture, alternately wet and dry

• XD3: attack by chlorides such as de-icing salt, alternating wet and dry

• XS3: tidal, splash and spray zone

• XF4: frost, with or without de-icing salts: high water saturation with de-icing salts

• XA3: highly aggressive chemical environment according to table 2 of NBN EN 206: 2013 + A2: 2021

Environmental classes (NBN B 15-001:2018):

• EE4: frost and de-icing salts (presence of locally thawed deicing water)

• ES4: sea environment: tidal and splash zone

• EA3: highly aggressive chemical environment

Design principles infrastructure:

Concrete strength class: high-strength concrete C60/75

Environmental classes (NBN EN 206):

• XC4: alternating wet and dry

• XD3: alternating wet and dry, in contact with chlorides (de-icing salts)

• XF4: high water saturation with de-icing salts

• Others on request

Environmental classes (NBN B 15-001):

• EE4: frost and de-icing salts

• Others on request

The following properties are taken into account with respect to the backfill material:

• Internal friction angle: k = 32.5°

• Weight by volume: k = 18 kN/m3

Concrete quality:

- Self-compacting concrete (very low water absorption)

- Highest resistance to acids (longer service life)

- All walls provided with reinforcement

- Own lab with daily quality control

- Certificates as a guarantee for a high quality product

Certificats

Decision

Soil

Quality

BENOR

CE

KOMO

agri

KOMO

infra

Efflorescence or lime deposit!

Efflorescence or lime deposit - a natural phenomenon that can occur with all cement-based products, including concrete elements, concrete structures, and facing bricks. Although it may sometimes seem concerning, lime deposit has no impact on the quality of your product.

This phenomenon occurs under specific climatic conditions. When water forms a thin film on the surface of concrete, lime is released and dissolves in this water film. After evaporation of the water, the lime deposits on the stones. Under the influence of CO2 from the air, the lime is converted into a white veil of calcium carbonate, which deposits on the stones.

The good news? Lime efflorescence disappears on its own, just as it appears. With plenty of rain and regular use of paving, this natural process can even be accelerated. In short, although lime efflorescence may cause temporary concerns, it is ultimately a completely harmless and self-regulating phenomenon.

Do not use acidic products to combat lime efflorescence, only water. Also, do not use a high-pressure cleaner. High-pressure washing damages the surface of concrete products, making the concrete more porous and more susceptible to algae and moss.

In case of frost, you don't need to do anything, as all ground elements from CBS Beton are resistant to frost and cold weather. Be careful with the use of de-icing salt or de-icing pellets: the range of Tiles - Steps - Benches & Edging is not resistant to de-icing salt or de-icing pellets. Never leave piles of de-icing salt. The accumulated salt can damage the surface of the concrete elements.