SILAGE CLAMP PANELS

SILAGE CLAMP PANELS FOR MAIZE, GRASS AND BIOGAS

SILAGE CLAMP PANELS UP TO 15 TONS AXLE LOAD

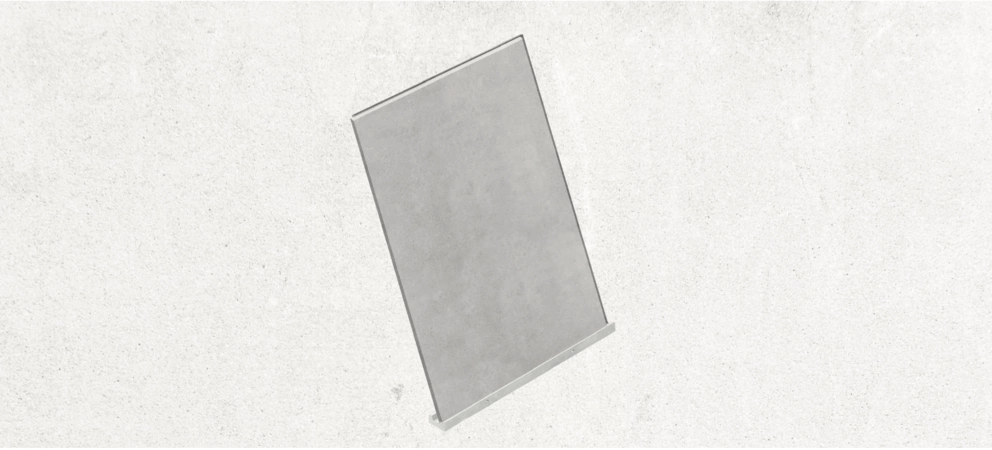

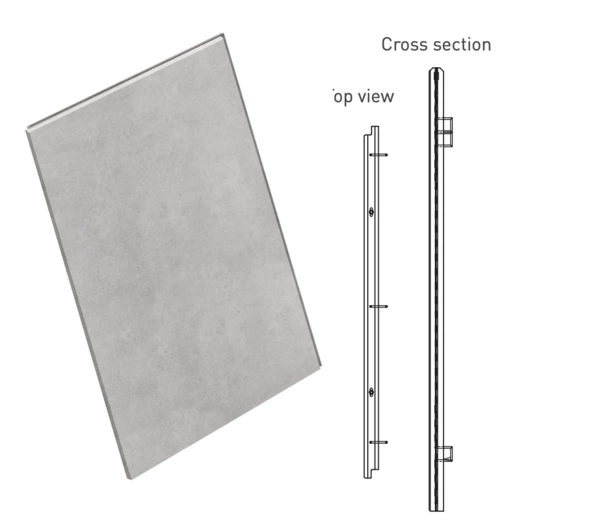

1) The Wall: CSWP310x240 - CSWP410x240

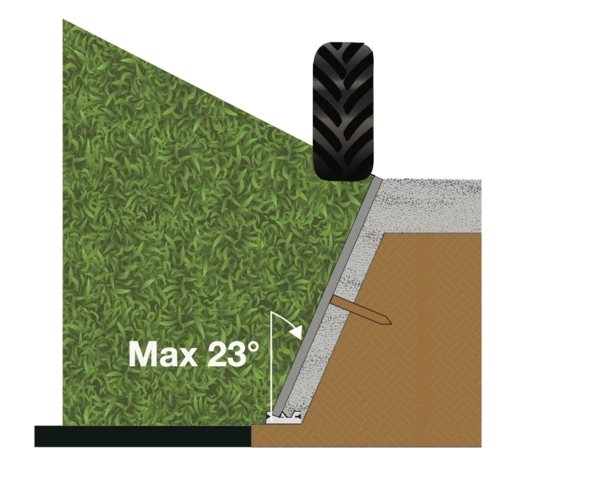

An CBS Beton silage clamp has a sloping wall at 23 degrees.Each pre-cast panel rests against an earth bank, which eliminates any movement of the panels. The earth banks also provide a safe and stable platform to work on – particularly useful when draping the clamp.

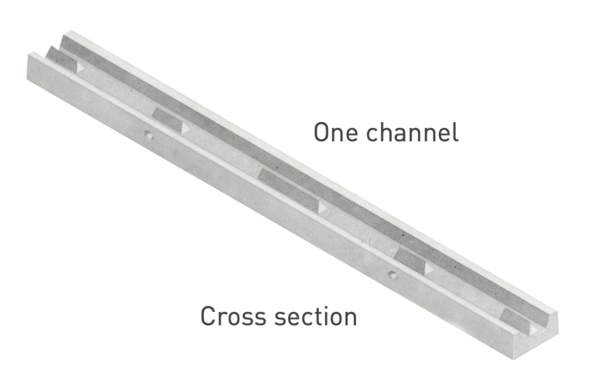

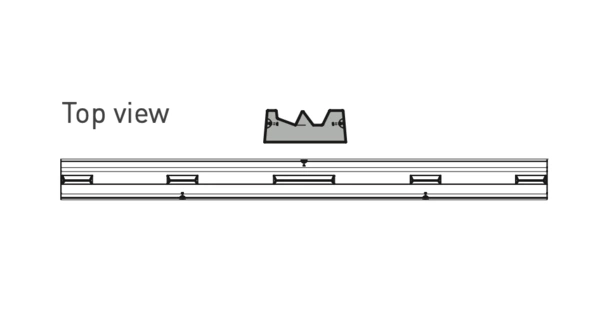

2) The seating channels: CSSC310 45x480 - CSSC410 45x480

Our CBS Beton sloping panels are always sited on one “seating channel”; that supports the panels. The seating channel has 1 channel with an upper (front) recess that supports the wall panels, and a lower (back) recess acts as a drain should leachate penetrate the wall. The seating channels are set below the surface of the silo floor so that the flooring material covers the top of the channel.

Although there is little likelihood of Leachate leakage through thewall panel joints, the concrete seating channel incorporates a collection drain, thus complying with the SSAFO regulations which require Leachate drains. (The Control of Pollution (Silage, Slurry and Agri- cultural Fuel Oil) behind the walls. These channels are connected to

SILAGE CLAMP PANELS 15 TON, SINGEL LOADED

SEATING CHANNELS

Download leaflet

MODIFIED/ADDITIONAL ELEMENTS

Freestanding

| Axle loads Panels | |

|---|---|

| PRODUCT | FREESTANDING |

| CSWP 310x240 | 15 ton |

| CSWP 410 x 240 | 15 ton |

Axle load

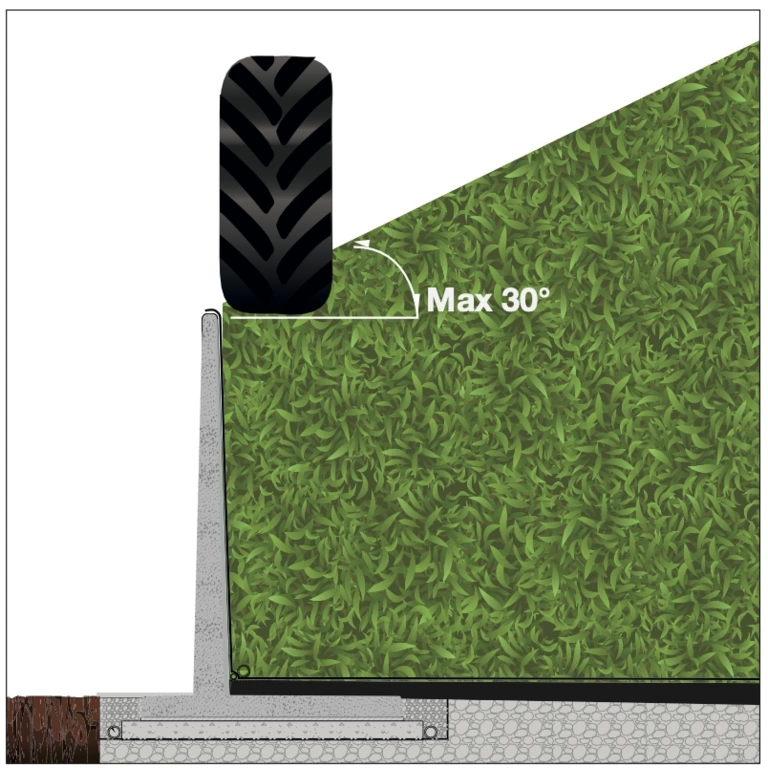

The axle load is calculated by dividing the mass of the compactor by the number of axles (so usually by 2). At CBS Beton, all walls are calculated with an edge clearance of 0 cm so that you can drive over the full width of your silo. Here, CBS Beton meets the strictest standards. When choosing your new silo, it is very important to check both the axle load and the edge Max 30°

clearance. The use of tandem and tridem combinations requires a special calculation. If you want to drive these machines to the edge, it is best to contact our engineering office.

An edge distance of 0 cm!

Our silo walls are designed so you can be drive right up to the edge. This allows the entire width of the silo to be used to compact the silage. This is the best way to preserve your silage.

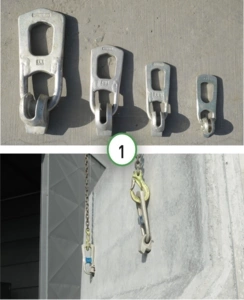

TYPES OF LIFTING HOOKS

The following lifting hooks are required to move the walls.

See technical sheet for lifting hooks needed for different types of walls.

Ball head anchors (1) = KKA

Rotating lifting point = RD20