Silobloc

NEW TRENCH SILO SYSTEM UP TO 10 TONS AXLE LOAD

Silobloc as partition Wall Between Two Silos - Double Retaining

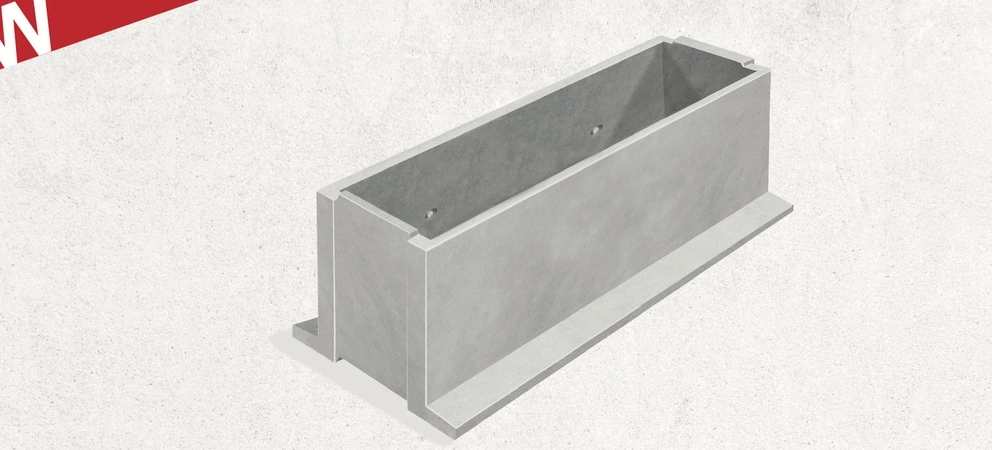

The Silobloc system is a new system of blocks for the construction of trench silos. It represents an excellent alternative to traditional trench silo walls: they weigh less and are easy to stack. The elements are connected horizontally and vertically with a tongue-and-groove joint, so that the blocks form a stable whole. Before commissioning the trench silo, the bins should be filled with crushed stone or sand. Always check that the soil has sufficient bearing capacity.

Features

• Quick and easy installation

• Walls can be raised afterwards

• Walls are connected horizontally and vertically with a tongue and groove joint

• Practical for dividing existing silo

SILOBLOC WITHOUT HEEL OR WITH CIRCULATION CORRIDOR, 10 TONS AXLE LOAD

SILOBLOC WITH HEEL, 10 TON AXLE LOAD

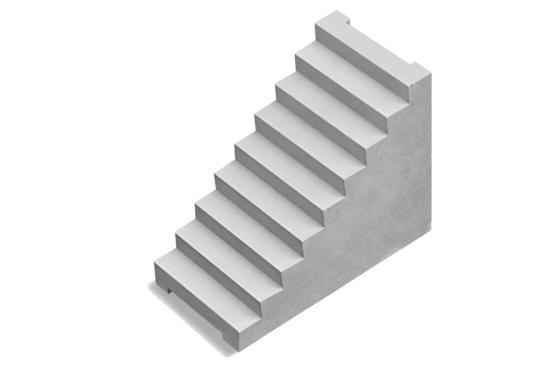

SILOBLOC STAIRS

SILOBLOC Cover plate

Silobloc range

Possible Implementation

CSBLOCB without heel

Silobloc with heel and base plat

Silobloc with heel

CSBLOCZ Silobloc with heel and base plate

CSBLOCC WITH CIRCULATION CORRIDOR

CSBLOCT Stairs

BLOC combinations

CSBLOCP cover plate

SILOBLOC WITHOUT HEEL, 10 TON AXLE LOAD

SILOBLOC WITH HEEL, 10 TON AXLE LOAD

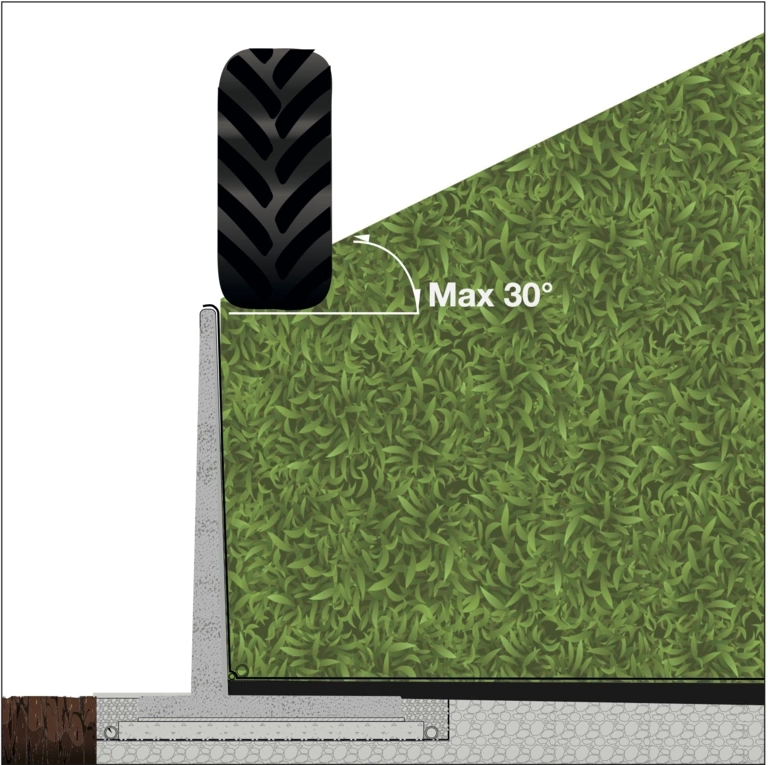

Axle load

The axle load is calculated by dividing the mass of the compactor by the number of axles (so usually by 2). At CBS Beton, all walls are calculated with an edge clearance of 0 cm so that you can drive over the full width of your silo. Here, CBS Beton meets the strictest standards. When choosing your new silo, it is very important to check both the axle load and the edge clearance. The use of tandem and tridem combinations requires a special calculation. If you want to drive these machines to the edge, it is best to contact our engineering office.

An edge distance of 0 cm!

Our silo walls are designed so you can be drive right up to the edge. This allows the entire width of the silo to be used to compact the silage. This is the best way to preserve your silage.

ACCESSORIES FOR INSTALLATION RETAINING WALLS

Om de wanden te verplaatsen zijn volgende hefhaken vereist.

See technical sheet which lifting hooks are needed for which type of walls.

Ring Clutches (1) = KKA

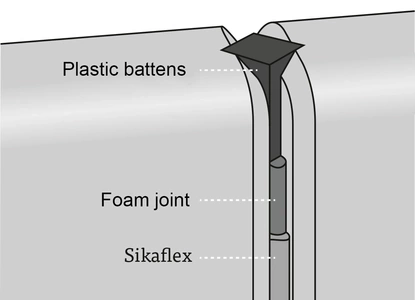

PVC BATTENS

PVC battens of 3 cm are placed between the walls. Advantages are: they will not crack or splinter, in addition, the battens do not absorb moisture and cannot rot. They retain their mechanical properties at temperatures between -18 and + 50 degrees Celsius.

To use less Sikaflex, foam joints are also placed between the high walls to reduce the cost.

SEALING

SIKAFLEX

For walls placed side by side, we apply a Sikaflex joint sealant with a filler gun. The installer applies Sikaflex to each side of the wall to create a strong joint. This is called sealant.

CBS Beton can supply the backfill strips, foam joints, joint gun and Sikaf- lex joint sealant.